Acciona Agua-Empresa Innovadora

Acciona Agua fue premiada en 2013 con los premios GLOBAL WALTER AWARD, como mejor empresa del año en desalación. Es una empresa que ejecuta proyectos en zonas de sequía como África o Australia. Tiene soluciones innovadoras ante problemas de agua potable como la potabilizadora de Marruecos. Y cuenta con la depuradora más grande del mundo en México (Depuradora de Atotonilco).

En cuanto a las líneas en depuración y reutilización, Acciona Agua destacan por:

- La optimizacion energética de las depuradoras.

- La minimización de lodos.

- Reutilización avanzada del agua depurada.

Pero vamos a centrarnos en un ejemplo claro de innovación por parte de Acciona Agua ante la creación de la Desaladora de Torrevieja. Esta es la instalación de mayor capacidad de producción con 240.000 m3/d, así como la mayor de Europa y la segunda del mundo con la tecnología de ósmosis inversa.

Esta es la instalación de mayor capacidad de producción con 240.000 m3/d, así como la mayor de Europa y la segunda del mundo con la tecnología de ósmosis inversa.

¿y que es la ósmosis inversa? es un proceso en el que se obtiene agua dulce del agua salada.La ósmosis inversa consiste en hacer pasar por un membrana semipermeable el disolvente (en este caso agua) desde el lado donde está la solución más concentrada (el agua de mar, con sales disueltas), hacia el lado contrario, sin que pasen las sales.

En su diseño se utilizaron los últimos avances tecnológicos encaminados tanto a la protección de las membranas de ósmosis inversa (filtros sumergidos en la captación, filtración en dos etapas sobre lecho dual, reactivos como coagulantes, antiescalantes, desinfectantes,..) como de reducción del consumo energético (bombas de alto rendimiento, recuperadores de energía por cámaras isobáricas, bombas de alimentación diferenciada,..).

La planta se diseño no sólo para producir un agua que cumpla la actual legislación en cuanto a abastecimiento, sino también con niveles de exigencia (boro <0,5 mgr/l) que permiten su uso en todo tipo de riegos agrícolas. El diseño de la instalación se ha completado con un avanzado estudio de integración paisajística con el entorno, edificios bioclimáticos e instalación de energía solar tanto térmica como eléctrica.

La instalación viene a cubrir un déficit de riego en la zona regable del trasvase Tajo-Segura de 60 Hm3/año y un déficit de abastecimiento en la «Vega Baja Oeste» de 20 Hm3/año. La instalación se ha diseñado para producir 80 Hm3/año (240.000 m3/día) en la actualidad, con posibilidades de ampliación a 120 Hm3/año.

*fuente: http://www.acciona-agua.es/innovacion.aspx

Agua en la certificación LEED

Recientemente Acciona Agua ha obtenido la certificación LEED ORO para sus oficinas de Cáceres. Esta certificación se otorga a los edificios que cumplen la norma Americana de Eficiencia Energética y Sostenibilidad. Al certificar un edificio se tienen en consideración estos … Sigue leyendo

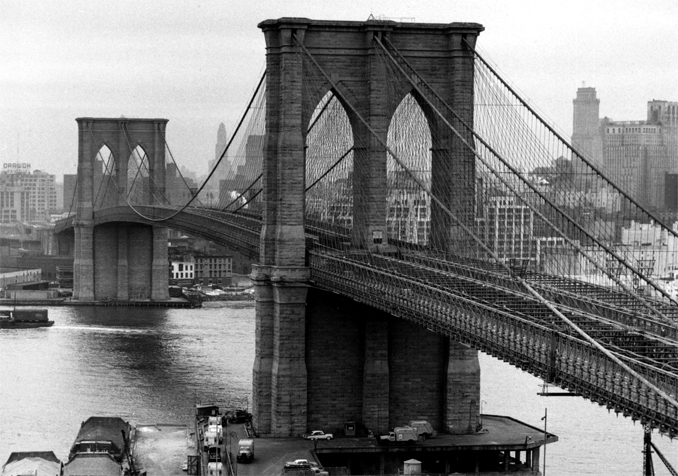

Project Management: Brooklyn Bridge

The Brooklyn Bridge, designed and built by John Roebling and son, is a masterpiece of engineering that has particularly fascinated me, as a civil engineer. If we stop to think, when it was built most of the constructions were real challenges for engineers of the time. The main challenges that their creators were found, have been collected in summary form in this post and they showed a remarkable degree of project management skill.

- Brooklyn Bridge, New York.

Planning the project: Successful execution in the longest suspension bridge until that moment, result of good planning and involvement by the Roeblings.

Customer management: Political controversy, because linking two municipalities, as were the suburbs of Brooklyn with the business district of Manhattan, they had to deal with the interests of both stakeholders, and the increasing jealousy from their competitors.

Another challenge Roebling had to face was the financing of the bridge, which came from both municipal governments and private industry. Financing was not always received according to the project plan which not only made completion of the project to any sort of schedule difficult, it also increased the cost of the project.

Managing Change: The first change request for the project was received before work had actually started, and it came up to anticipate future demand. The change request was to increase the carrying capacity of the bridge and this was followed by the request of changing the projected pilings as foundations for the twin towers of the bridge into foundations that needed to rest on bedrock.

Corrective Action: The challenge now was how to dig that magnitude of hole, at that deep underwater.

The solution Roebling made up was caissons, based on the diving bell, proving his ability to learn quickly and avoid unnecessary mistakes. Water tight structures lowered into the river until they rest on the bottom. Then, with compressed air pumped into these caissons, they could create a breathable atmosphere where the workers could perform their digging.

Manual excavation would have taken forever and Roebling decided to use dynamite to speed the process. Until that time this all was new for bridge building, so Roebling and his team had to improvise these solutions on the fly, without having an opportunity to prove his methods with pilots.

In the Brooklyn Bridge was also the first time that steel was used for the cables that supported the bridge deck instead of iron as had been done so far.

Managing the Risks: Find a solution to perform safely and invented a new technical solution. Sorry for the repetition, but it is true that the Brooklyn Bridge was a bridge of many firsts, that had to be manage with new security measures associated.

Think Lean

Lean construction is a philosophy that comes from the concepts of Lean Manufacturing, system developed by the large Japanese car manufacturers, initially introduced by Toyota. Its objectives are, broadly speaking, maximizing value and minimizing waste. This way of thinking has transformed many industries, and it has a lot of potential benefits for construction.

One of the foundations of this philosophy is the people. Real and effective collaboration among all the stakeholders is essential, and everyone should be treated as equal, increasing the ‘team feeling’ and everyone’s satisfaction. That is why lean always focuses on keeping workers motivated and involved, through information sharing and useful feedbacks.

Other important principles are continuous improvement and innovation, from the top of the company to the bottom, and elimination of all kinds waste. Waste not in the usual meaning, but mistakes, redundant activities , delayed imputs or messy work places.

One successful example of how Lean thinking can improve project outcomes in construction is the Temecula Valley Hospital, in California. The project cost was down to $1.1 million per bed, when the average in this state is $2.0 million. And also the project was finished 4 months faster than the initial schedule, isn`t it great? Lean manufacturing techniques, 3D modeling, innovation and collaboration were key.

Eventhough manufacturing and project management in construction have several differences, its principles can be adapted to many other fields, and multiple examples shows how lean construction implementation can help to reduce costs and make work more efficient.

Airbus – A380, la toma de decisiones en proyectos

El avión comercial más grande del mundo se puede considerar un logro de la ingeniería. Con capacidad de 850 pasajeros y con mas envergadura que un estadio de futbol. Teniendo programa su entrega para 2006, la entrada en servicio de … Sigue leyendo

IBERDROLA RENEWABLES, National Control Center.

Past two weeks I have the oppotunity to visit the city of Portland, Oregon, with several colleagues who are studying different masters related to sustainability and environment in the EOI. My partners and me have known really amazing companies and people, that have shown their different (or in some cases not so different) ways of make business.

Of all the companies we met, the coordinators, Mary and Kate, were also able to close a visit with a business requested by my colleagues who are studying renewable energies: IBERDROLA RENEWABLES. I was one of the lucky students that could access inside the National Control Center of Renewables which IBERDROLA RENEWABLES has located in Portland.

Launched in 2010, the Control Center of Portland has become today in the latest installation of renewable energy in the U.S. From the center, technicians can control and operate in real time, 24 hours a day 365 days a year, all the wind parks and associated substations the company has in the U.S. In addition, the center also receives information from the rest of the parks of IBERDROLA in the world.

We were able to access the control room where workers showed us how to operate and how monitors collect all activity in real time. As they commented us, they need to store all information received from each wind farm, each of which has a control system and local information which includes the main operating variables of the machines and electrical substation. They even control the number of fallen birds due to aerogenerators.

Then, operators can quickly detect malfunctions or stops and make a remote analysis. After analysis, they make appropriate decisions for the resolution, either from the same control center or by local operation or maintenance checkpoints the company has in each wind farm. Thus, downtime due to breakdowns are reduced and plant availability is increased.

Also from the center, operators control the amount of energy discharged to the grid based on demand, which in turn equally affects the price, making every 5 minutes everything can change.

On the other side, the safety of the facilities is improved with the installation of a monitoring system on site with cameras connected to the center.

For the operation, the Control Center has a separate control computer system, compatible with all manufacturers of which the center controls some type of wind turbine. Also meets the standards of safety and reliability required in the United States.

One of my partners asked the speaker about the land where they install the aerogenerators. As he could explain us, when they have a possible new position for a wind farm, they first spend about two years controlling the amount of wind in the area, and if the results are favorable, they have to compensate the farmers who are the owners of the lands to adquire them.

I have to say that while the world of renewable energy was unknown to me, I was pretty impressed with what I’ve discovered during this trip. Especially with the facilities IBERDROLA RENEWABLES has implanted in Portland, because of course, being a Spanish company, makes you feel even more proud of how well the brand Spain is working in this sector and is well positioned in the world.

Columbia Corporate Social Responsibility

The last day of our study trip in Portland were visiting Columbia to its headquarters, the company manufactures and distributes sportswear, footwear and outdoor sports equipment. Founded in 1938 by the late Paul Lamfrom, father of the current president of the company Gert Boyle.

During our visit to Columbia they explained to us how they develop their sustainability. In the case of this company talked about different corporate social responsibility programs.

Corporate responsibility at Columbia

They are committed to building a company of which we can all be proud- not only of the innovative products they created and the financial results they achieve, but the manner in which they achieve them. Whether it’s responsible sourcing, giving back to our communities, or reducing our environmental impact, they believe that corporate responsibility is a companywide effort.

Emotional Connection of Columbia

They did an emotional study because they think that emotions influence our thinking more than our thinking influences our emotions, as 90% of human decisions are emotional rather than rational.

This study obtained the following data:

- Current consumer Trends in the US: 85% have more positive image of as product or company when it supports a cause they care about and the 83% of customers want more of the products, services, and retailers they use to benefit causes.

- International and Emerging Markets: Nearly 8 in 10 consumers in Brazil and Mexico would buy products from companies that support good causes, compared to just over one half in major Western European economies and despite the prolonged global recession, 66% of global consumers report that they are likely to buy and recommend companies that support a good cause.

Strategic Giving of Columbia

From emotional study Columbia did strategic giving, it is a conscious attempt by a company to invest resources to bring about change in a set of social, economics, or environmental circumstances seen as relevant to the business in which the company is operating.

They work in different programs about good causes like:

- GOA Belay Program: Columbia was invited by GOA for the third straight year to open up their annual meeting at Winter OR and be recognized for them partnership. This program has successfully invested $110000 to complete 22 locally-identified, critical conservation projects across the country.

- Collegiate Outdoor Recreation: Invest in an unprecedented opportunity to expand outdoor market with 18-35 year olds through accessible national network. With this program Columbia try enhancing brand perception and creating emotional connection with young adults and connecting collegiate recreational and team sports market to Columbia and outdoor activities. Lead coalition to provide sustainable support though product donations to the “pipeline” of future consumers.

Columbia has more programs about different things, among these highlighted: HERproject, Save Our Seagrass, CCA / Academy and Tested Tough in Pink Update (about cancer)

Study Trip Day 2: Costco oversees

Costco is a consolidated company in the United States that are focused on retail sector. This company is focused to ward sustainability . That means the company are not taking great risk investments that could get the company into problems. The … Sigue leyendo

The Rebuilding Center

Wednesday March 5 , within the “Study Programme trip at the University of Portland on sustainabilitiy and economic development” , we visited the company The ReBuilding Center, located in the north of the city of Portland (Oregon , USA)

The ReBuilding Center, a project of Our Villages, is emerging as a dynamic resource for strengthening the economic and social environmental fabric of local communities .

Provides resources that make home repairs affordable for all , in order to promote the reuse of recovered materials and regenerated in your store have a large inventory of sinks, tubs , tiles, wood , doors, windows …

Also store reuse, ReBuilding includes DeConstruction Services Center , a sustainable alternative to conventional demolition. Another project underway is to rediscover Education, which offers workshops and classes on how to work safely and creatively with the construction materials used .His collection service is free , also offer volunteer opportunities with purpose and donated building materials used for community projects.

The Rebuildin Center accepts the region´s largest volume of used building and remodeling materials, providing resources for the benefit of communities with the goal of promoting sustainable practices.

El “Know how” adquirido

El programa AGUA nació con la razón de realizar actuaciones garantizasen la disponibilidad y calidad del agua en toda España. Mediante la utilización de los avances tecnológicos se busco soluciones eficaces para los problemas que se plantearon. La desalinización por … Sigue leyendo

.png)

].gif)

.png)

].png)

].png)

].png)

.png)

].png)

.png)